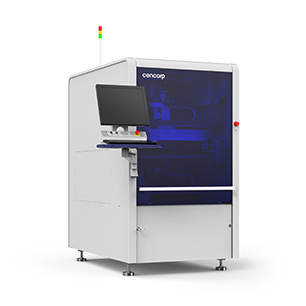

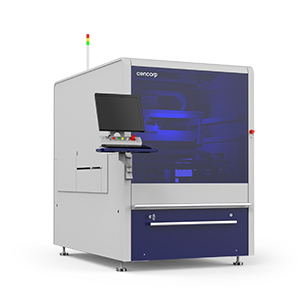

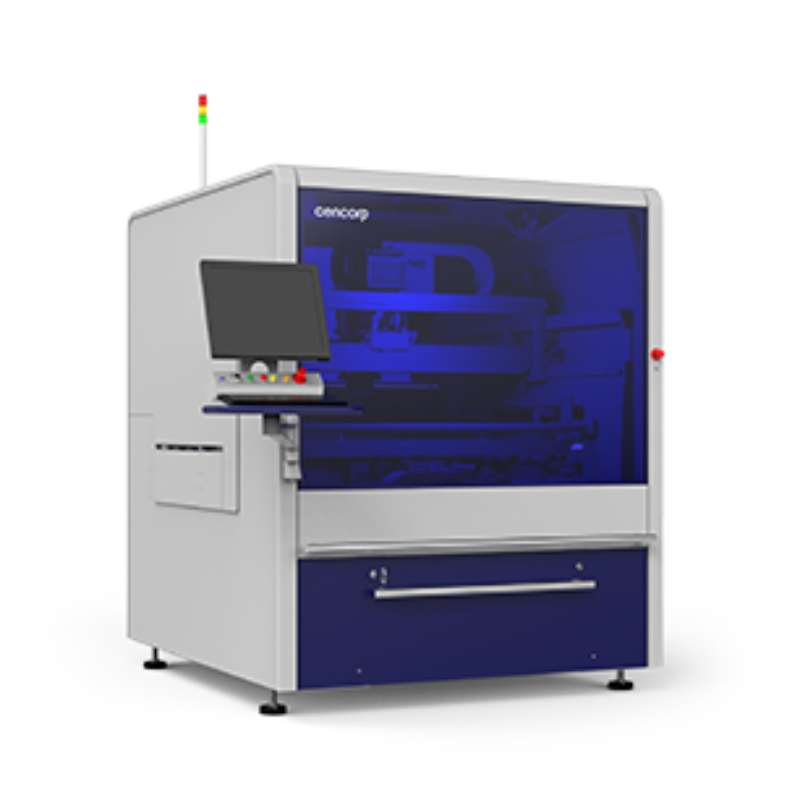

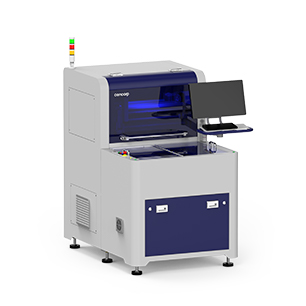

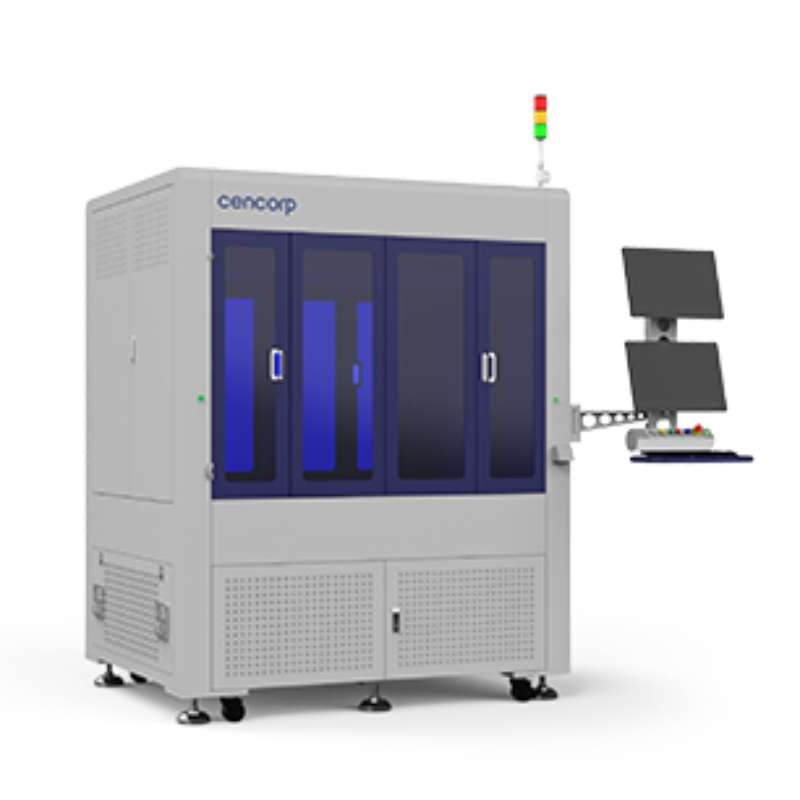

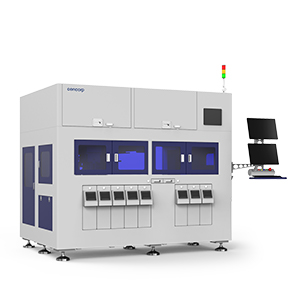

1300 BR

Inline Depaneling Equipment

cencorp 1300 BR has depaneling capability of high speed and high precision. It provides you solution with high efficiency, stabilization and low maintenance cost by equipped with linear motor.

cencorp 1300 BR is designed for high volume mass-production. The fast product change-over can guarantee a high through-put and minimize production loss.

To fulfill the strict requirement of depaneling from customer, 1300 BR integrates dust cleaning and ionizer. Also, considering of user and service friendliness, 1300 BR is easy to access inside of the equipment from front and rear sides.

Cencorp 1300 BR is equipped with software that can generate daily production report easily. Our software also provides functions such as PCB quality verification, bit height & diameter verification, CAD file download, offline programming etc.